Our manufacture is based on single and double sawing. The sawmill is equipped with Wood-Mizer LT40 horizontal sawing machines, as well as the well-acclaimed PK-60 vertical sawing machines. We also employ multiple edgers and multi-saws.

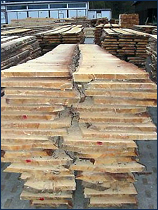

Sawing of 186-years-old pine

(Zdrojowa Gora Forest Inspectorate)

Sawing of 186-years-old pine

(Zdrojowa Gora Forest Inspectorate) Wood-Mizer edgers

Wood-Mizer edgersTotal capacity of our machines and professional equipment operation make it possible for us to accept and carry out several orders simultaneously. The production profile is not based on storing sawn timber – we treat customers individually and carry out orders and fulfill all the specific requests of the particular customer.

In our company the key element of all internal processes is the so-called ‘machine plant’. The wood brought from the forest by special vehicles is immediately sorted into specific assortments and stored on special piles designed especially for this purpose. Properly trained saw operators can process up to 100 cu. metres of large-size wood during one shift. Such results can be obtained only by means of specialised equipment. The work is fully automated.

Large-size wood transportation

Large-size wood transportation Basic raw material for a sawmill

Basic raw material for a sawmillThe “semi-finished product” is transported to the “sawn timber area” which is capable of storaging about 800 cu. metres of sawn timber. The sawn timber is then duly labelled and prepared for shipping. The whole process is supervised by qualified technical staff as it is the most important to maintain and meet the highest quality requirements demanded by our customers.

The products are shipped by means of our own special vehicles with a loading capacity of up to 24 tonnes.